Service Bulletin June 2017

- Heat-Treatment Test

- Sepos Returns

- Expert Tip

A proper heat-treatment of the springs at 300°C is essential and gets the best results for high quality springs. If a spring does not get heat-treated properly at the right temperature - the loss of height is much bigger.

The spring test shows you the different loss of heights of 3 springs with same specifications but heat treated at different temperatures: first spring at 0°C – second at 150°C – and the third at 300°C.

A perfect heat-treatment guarantees a high quality spring, avoids sagging and saves wire.

It is worth to check temperature on your machines.

Temperature sticks are available at Spühl.

Part no. 94.93705.60 274°C

Part no. 94.93705.70 316°C

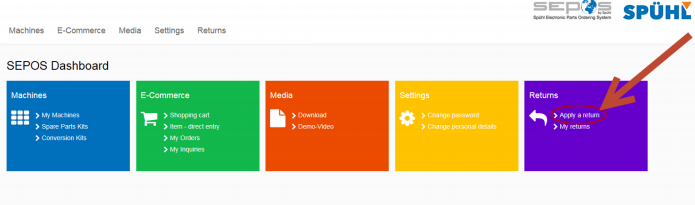

New since 1st of February, the return system was released via SEPOS (See E-Mail of 27 January 2017). The advantage to us is that we get all the information we need beforehand. The advantage for you is that you can check the status of your returns at any time. In addition, you have a simple overview of all ongoing and completed returns. The system is very simple, but if you have any questions, please feel free to contact us or read the Quick Start Guide.

Due to complaints about sweat failure Within just a few days of production, Spühl GmbH, together with SwissSonic, investigated failed sonotrodes and the reasons for the failure. The following compilation was derived from these experiences: Lessons Learned - Welding Horn Failures. It is worth reading.